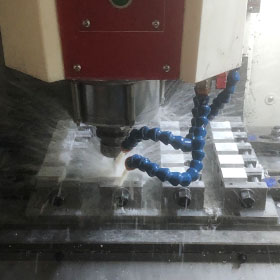

Precision CNC Machining

CNC turning and milling

Gambo Industry is a ISO 9001:2015 certified company. With our Various maching equipment, these include CNC Lathes, CNC Milling, Drilling Centers and CNC Machining Centers. Gambo provides precision CNC machining of numerous materials, including stainless steel, aluminum, brass, steel,castings, forgings and UHMW.

Gambo Industry is a ISO 9001:2015 certified company. With our Various maching equipment, these include CNC Lathes, CNC Milling, Drilling Centers and CNC Machining Centers. Gambo provides precision CNC machining of numerous materials, including stainless steel, aluminum, brass, steel,castings, forgings and UHMW.

Our engineers select the ideal equipment for an application based on the geometry, material, and volume of the part being machined to provide customers with premium quality parts at the best possible price. We are able to hold very tight geometric tolerances for diameter, true position, profile, and flatness.

Our milling machines also offer through the spindle coolant and tool setters that can be used for tool breakage detection for longer run parts. we also offer a variety of other machining services, which cover the entire production process. Gambo has top-of-the-line machinery to tackle conventional milling, drilling, turning, and sawing, as well as grinding and honing, deburring, and part marking.

Through approved, certified vendors, we can also provide heat treating, welding, plating, and painting. Once your part is complete, Gambo follows through with complete inspection, assembly, and even customized packaging.

Precision Swiss CNC Machining

Small size parts also are Gambo's specialty. Swiss CNC machining is the most precise and efficient machining method for critical components. The modern CNC Swiss have a wide range of capabilities, spanning across many industries. This includes everything on land, sea and in air to life sustaining medical components.

Small size parts also are Gambo's specialty. Swiss CNC machining is the most precise and efficient machining method for critical components. The modern CNC Swiss have a wide range of capabilities, spanning across many industries. This includes everything on land, sea and in air to life sustaining medical components.

Our Swiss automatics with sub spindle and auto bar loaders are able to complete parts in one operation, including thread whirling, thread milling, polygon machining, slotting, broaching, angle cross milling.

Quantity & Delivery

Gambo Industry produce parts in many different quantities. We has areas devoted to producing one-piece prototypes, assembly fixtures, and short-run production. The lead time for prototype parts typically averages 1 to 2 weeks, while production runs average 4 to 6 weeks. Rush services are also available to accommodate emergency situations as needed.